The following tables list the tightening torque for the major fasteners requiring use of a non-permanent locking agent or silicone sealant etc.

Letters used in the “Remarks” column mean: AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque.

G: Apply grease.

L: Apply a non-permanent locking agent.

Lh: Left-hand Threads

MO: Apply molybdenum disulfide oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10:1)

R: Replacement Parts

S: Follow the specified tightening sequence.

Si: Apply silicone grease (ex. PBC grease).

SS: Apply silicone sealant.

The table below, relating tightening torque to thread diameter, lists the basic torque for the bolts and nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the values are for use with dry solvent-cleaned threads.

Basic Torque for General Fasteners

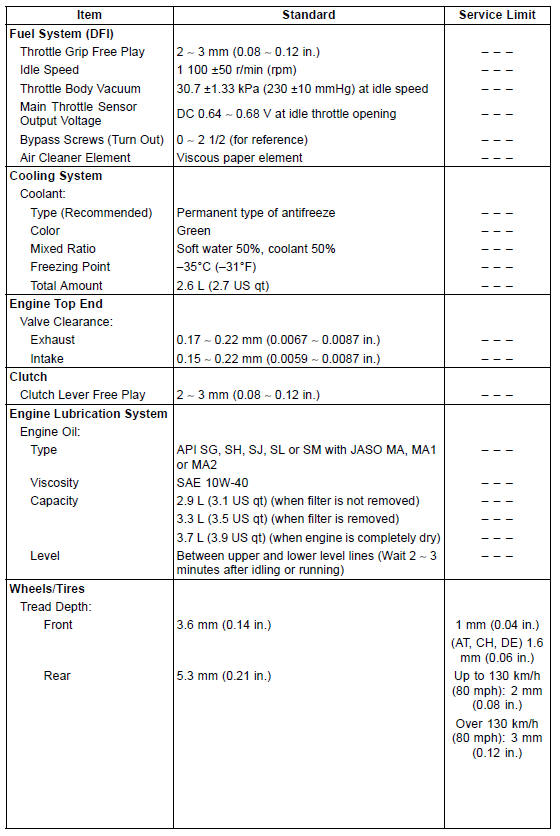

Specifications

Special Tools

Periodic Maintenance Chart

Periodic Maintenance ChartSelf-Diagnosis Procedures

NOTE

Use a fully charged battery when conducting

self-diagnosis. Otherwise, the light (LED) and symbol

do not light or blink.

Turn the ignition switch to ON.

When a problem occurs with DFI system and ignition system,

the warning indicator light (LED) [A] goes on and

FI warning symbol ...

Brake Lever Adjuster

There is an adjuster on the brake

lever. The adjuster has 6 positions so

that the released lever position can be

adjusted to suit the operator’s hands.

Push the lever forward and turn the adjuster

to align the number with the mark

on the lever holder. The distance from

the grip to the rel ...

KIBS Motor Relay Inspection (Service Code b 35)

Check the KIBS motor relay fuse (25 A) [A] (see Fuse

Inspection in the Electrical System chapter)

If the fuse is good, check the wiring continuity as follows.

Disconnect:

Battery Positive Cable (see Battery Removal in the Electrical

System chapter)

KIBS Hydraulic Unit Lead Connector (see ...