(For Products Sold in the United States of America, District of Columbia, and U.S. Territories Only)

If you believe that your vehicle has a defect which could cause a crash or could cause injury or death, you should immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to notifying Kawasaki Motors Corporation, U.S.A.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you, your dealer, or Kawasaki Motors Corporation, U.S.A.

To contact NHTSA, you may either call the Auto Safety Hotline toll-free at 1-800 -424-9393 (or 366-0123 in Washington, D.C. area) or write to: NHTSA, U.S. Department of Transportation, Washington, D.C. 20590. You can also obtain other information about motor vehicle safety from the Hotline.

Environmental protection

To help preserve the environment, properly discard used batteries, tires, oils and fluids, or other vehicle components that you might dispose of in the future. Consult your authorized Kawasaki dealer or local environmental waste agency for their proper disposal procedure. This also applies to disposal of the entire vehicle at the end of its life.

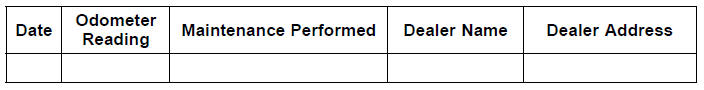

Maintenance record

Owner Name

Address

Phone Number

Engine Number

Vehicle Number

Key Code

Selling Dealer Name

Phone Number

Warranty Start Date

Note: Keep this information and a spare key in a secure location.

What if I am not Satisfied With My Warranty Service?

What if I am not Satisfied With My Warranty Service? Location of labels

Location of labelsBrake Disc Warp Inspection

Raise the wheel off the ground with the jack.

Special Tools - Jack: 57001-1238

Jack Attachment: 57001-1608

For front disc inspection, turn the handlebar fully to one

side.

Set up a dial gauge against the disc [A] as shown in

the figure and measure disc runout, while turning [B] the

...

Camshaft Chain Tensioner Installation

Replace the O-ring [A] with a new one.

Apply grease to the new O-ring.

Release the stopper [B] and push the push rod [C] into the

interior of the tensioner body [D] so that the position of the

push rod is 3 or 4 notches [E] as shown in the figure.

Install the tensioner body so that the ...

PassengerŌĆÖs Seat Installation

Insert the tab on the rear of the passengerŌĆÖs

seat into the slot in the

frame.

Insert the projections at the front of

the passengerŌĆÖs seat into the holes

on the frame.

Push down the front part of the passengerŌĆÖs

seat until the lock clicks.

A. PassengerŌĆÖs Seat

B. Proj ...